4 Grabouw close

Bellville, Cape Town

+27 82 889 2952

Direct Line or Whatsapp

8:00 - 17:00

Weekdays

Closed Weekends

- Lab Order

- Implant Planning Order

- Support Call

- Design Outsource

- Client Zone

Interested?

We are a digital cosmetic dental laboratory.

We specialise in a wide range of dental treatments.

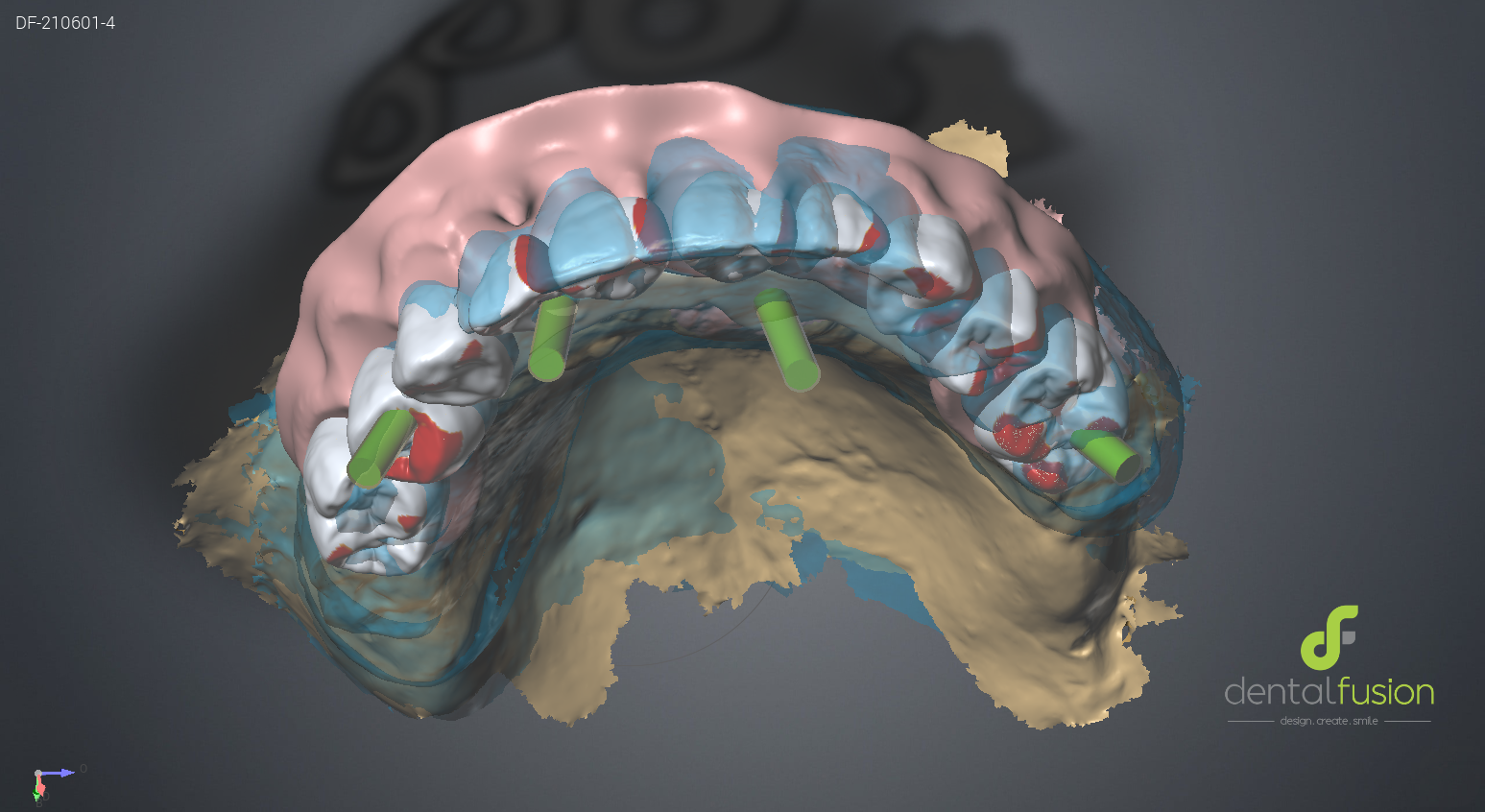

- Dental implant planning with printed surgical guides ensure predictable prosthetic results.

- Digital diagnostic wax-up with printed models to assist the dentist with treatment options for patients.

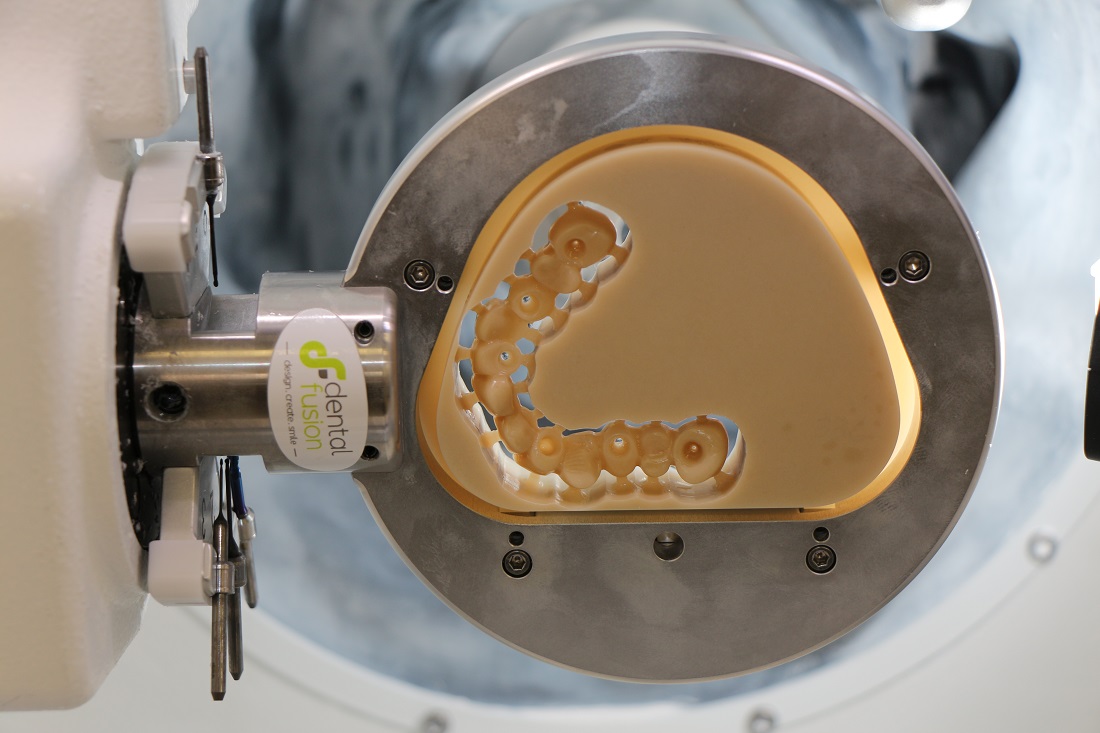

- With a combination of powerful design software and an accurate milling machine, we manufacture highly aesthetic crowns, bridges and substructures.

- Every case enjoys personal attention and is crafted with the highest quality materials.

- All validated by the Straumann Cares Digital workflow.

MOST COMMON treatments:

Monolithic Multilayer Crowns

Surgical guide Planning & Printing

implant Crowns

Specialised services:

Multi Implant Frameworks

Various implant interfaces available through our Medentika offering. From single crowns to full arch frameworks

Titanium Bars

Centrilized milling with Titanium BAR, Hybrids and Removables

Angulated implant solutions

Angulated milling solutions in Zirconia and Titanium

Full digital workflows

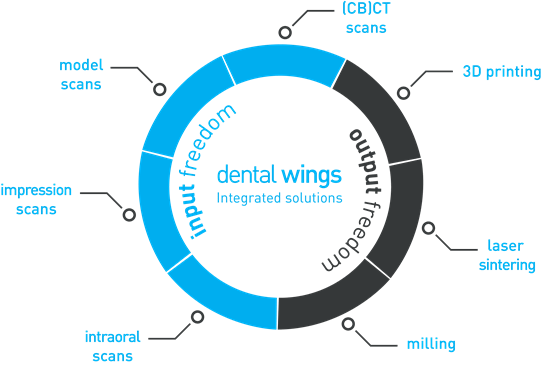

Complete digital solution from scan to crown placement. All Digital. Your STL come alive through our integrated system.

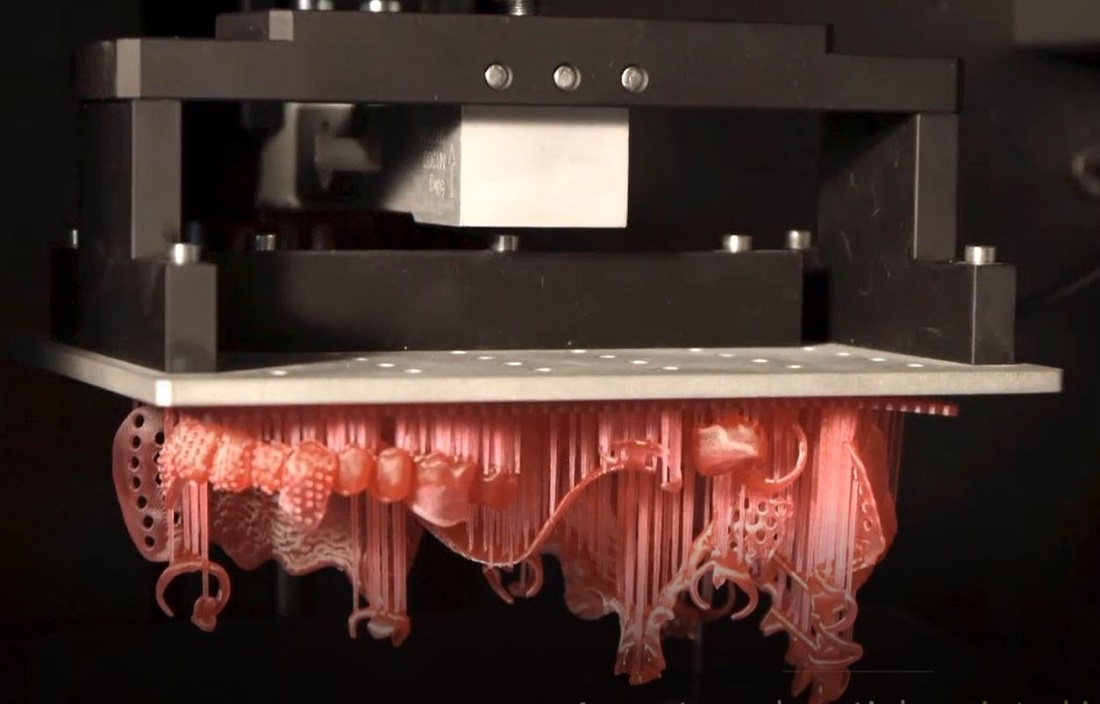

Digital printing service

Fast and reliable printing with various materials. Diagnostic designs, surgical guides, crown and bridge models and aligners to splints.

If you have something special in mind.. CALL US TODAY

+27 82 889 2952

Connect

Flexability is the Key. How do we work together?

At dental fusion, we cater for all disciplines in dental technology. We can process your case from analogue to full digital workflow.

Our workflow is simple and convenient. Download our digital work order in the top banner. Fill it out with your treatment plan. Submit the order and either send us your models or your digital data. We design and manufacture according to your requirements.

here are a vew ways to do it:

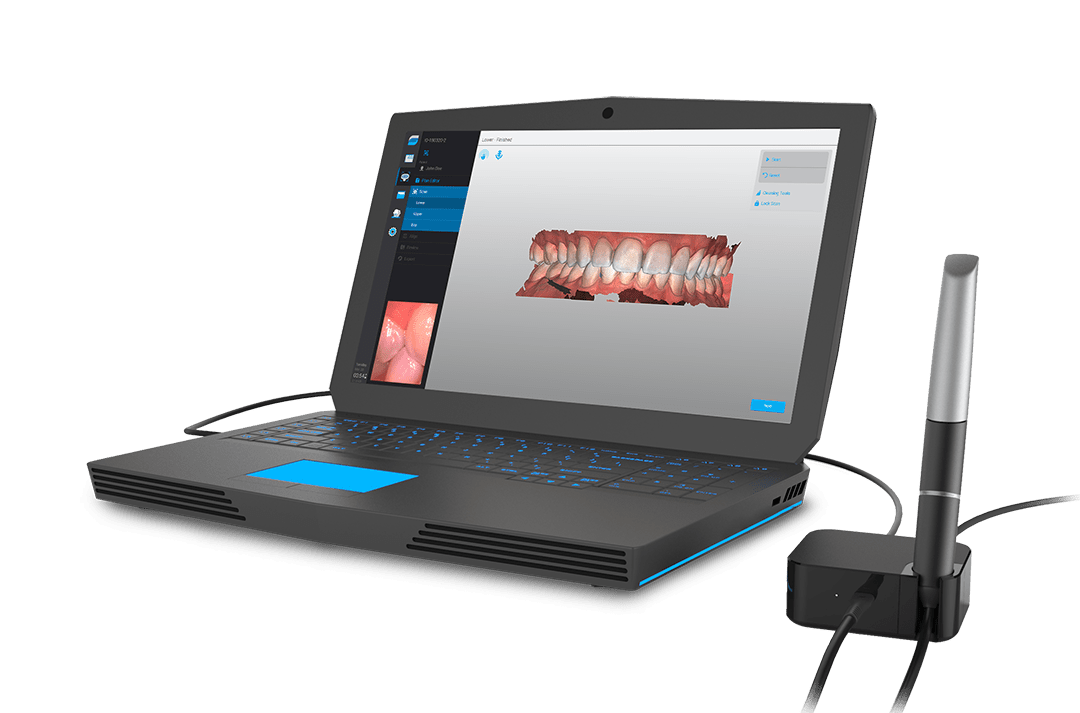

Intra-oral Scans STL

Send your STL files to us and we will make that smile happen in a few clicks. We return either the milled crown or the finished design.

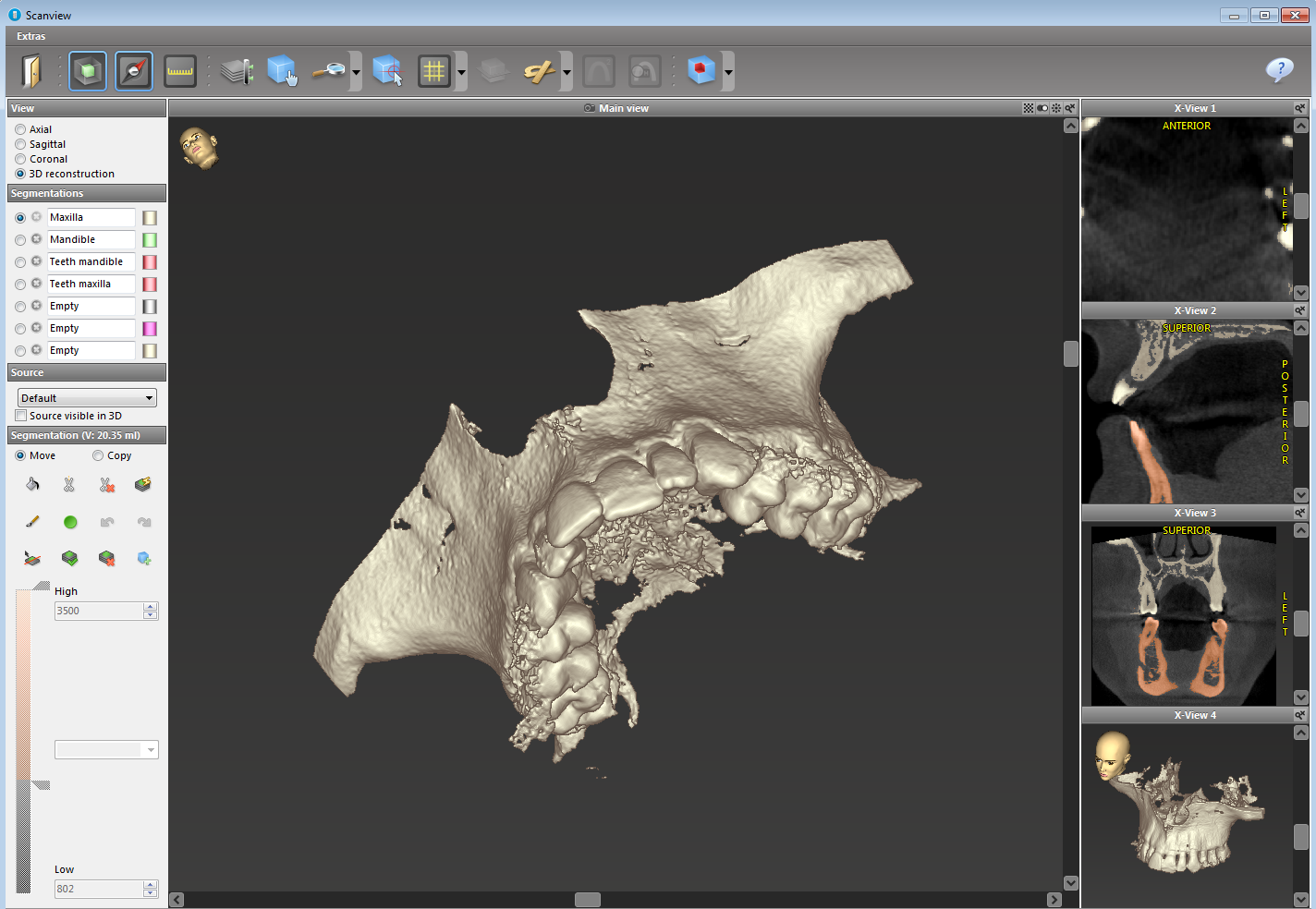

DICOM Transfer

For implant planning. Send your DICOM folder via Wetransfer and upload your treatment plan from the digital order. Its fast and secure. No case are to BIG or to small

Analogue

Dental impressions are still considered one of the most and accurate way of replicating your patient's features. Send us your models and we will digitize them.

3Shape Connect

From Trios to design in a few clicks. Just find us on the communicate platform and hit send.

why choose us

Why Dental Fusion?

We are a digital dental laboratory based in Durbanville Cape Town.

Specializing in cosmetic implant bourne dental restorations. The art of utilising modern digital tools to create very specialised dental products.

Advanced implant planning creates a predictable outcome for surgeons and restorative professionals with pinpoint guided tools.

Digital printing enables us to print models and guides and to showcase the possibilities of what could be achieved and beyond.

Our Straumann M-Series Inhouse milling unit ensures on hand quality and performance – with our direct link to international centralised milling we can do the unimaginable.

Our Straumann® validated materials are scientifically proven and of the highest quality available world wide.

With the wealth of experience of our ceramists beautiful smiles are crafted with passion.

– design . create . smile –

Here is a few highlights

Amann Girrbach 5-axis milling machine

The 5-axis milling unit combines wet and dry processing in one unit and enables the value-creation chain to be kept virtually completely in-house in the laboratory. A wide range of materials available to this portfolio make this a veristile tool in our lab.

Rapidshape 3d printing Technology

A flexible and certified 3D printing solution through its open material system with validated processes. This printer not only excels with top of the class quality, but also with a large print area and short production times.

Validated material selection

Our material range from Straumann Group Digital Solutions offers a unique portfolio to provide our patients and the restoration team with unprecedented variety of treatment options. All Validated and scientifically proven.

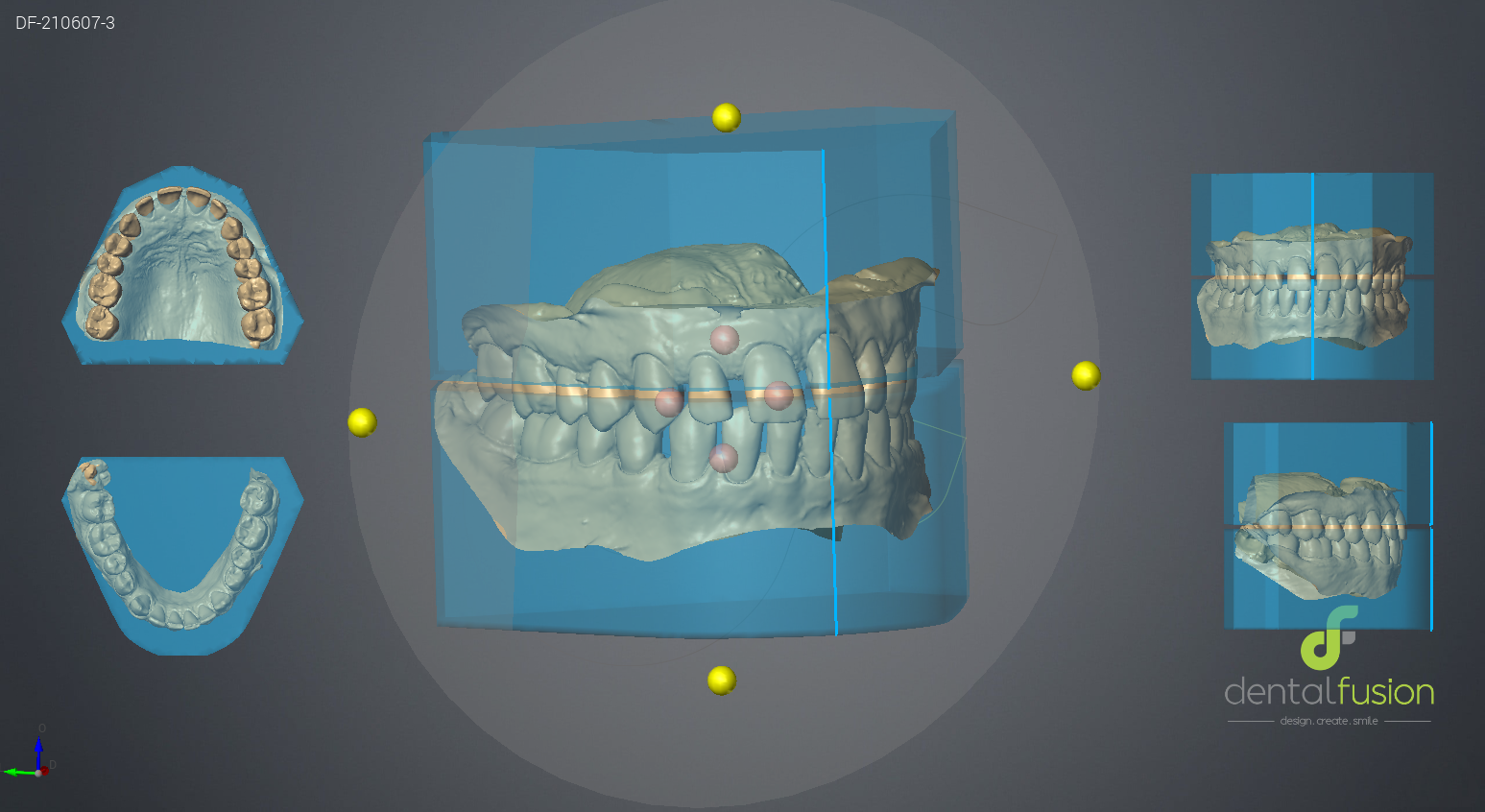

The Only validated CoDaignostiX Lab in Africa

We went the extra mile to validate our equipment, software and materials with CoDiagnostiX in Dusseldorf to be pin point accurate. With the guarantee of precision we create guides that can be used with confidence.

If you have something special in mind.. CALL US TODAY

+27 82 889 2952

Orthodontic Archiving

Orthodontic Archiving module allows dental professionals to scan models and impressions or import intraoral scans for the design of virtual orthodontic study models for digital archiving and manufacturing. Space saving and quick to retrieve via 3d printing.

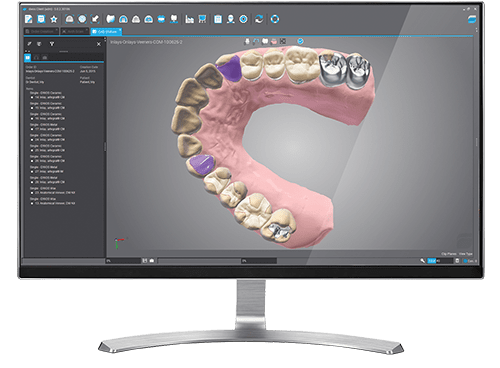

DentalWings - open architechture design software

The open architecture of DWOS offers flexibility to work with clinical information, design processes, and down-stream production processes as needed. Likewise, a wide range of materials, implant kits, crown anatomies, etc. are also made highly accessible.

Crown in a day

We offer a Crown in day service. With your STL intra oral scan, we design the prosthesis and Printed Resin crowns, Mill PMMA temp restorations, Ceramic restorations in Emax, N!ce and Ennamic.

Scan & shape

A design platform to deliver a piece of mind, quality customized prosthetics with no investment in equipment, technology, or training. A comprehensive level of on-demand design service for your restorative CADCAM needs. We provide service expertise from traditional implant-borne solutions to tooth-borne restorations. Implant planning with STL output format.

contact us

Still not sure? Contact us directly.

Our friendly team of technicians are ready to connect and answer any question | Request a quote is just a phone call away

We offer a Scan & shape service. We design your required restoration from the intraoral scans. Once checked we send you the completed restoration in STL format to manufacture anywhere in the world.

We need a copy of the uncompressed DICOM data folder for your patient, your treatment plan for the final prosthesis, planned implant positions and the implant manufacturer you wish to use. We compile the presentation plan and connect via AnyDesk for verification from the surgeon. After implants are locked in position by the surgeon we continue with guide manufacturing.

No layout cost or expensive software.

A Timesaver with low input cost.

Yes, for your bar designs, we need a try-in wax-up model, a plaster model with removable tissue around the lab analogues and your required finished result.

We scan and design to your requirements, and once confirmed by you. We send it for manufacturing.

For bar designs, we use two companies Createch and Straumann Centilized milling solutions. We are directly connected to their platform and follow validated workflow protocol for precision fit and lifetime warranty on our frames.